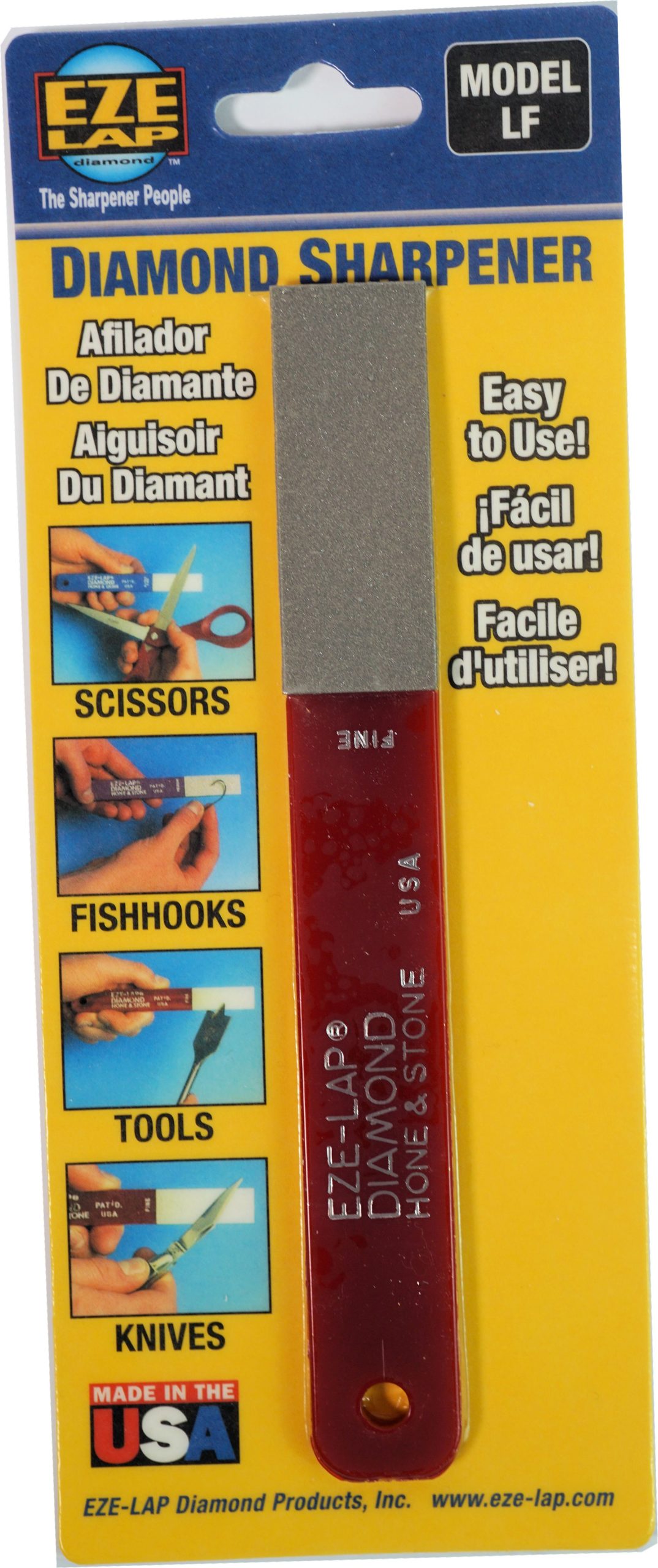

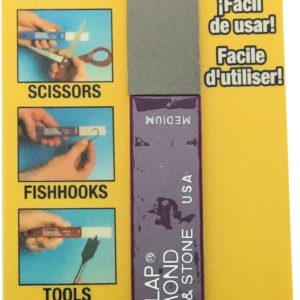

Very effective in hard to get places, carbide table saw blades, router bits, deburring. many uses include hunting and fishing knives, axes, woodworking tools and carbides. Fine 600 Grit.

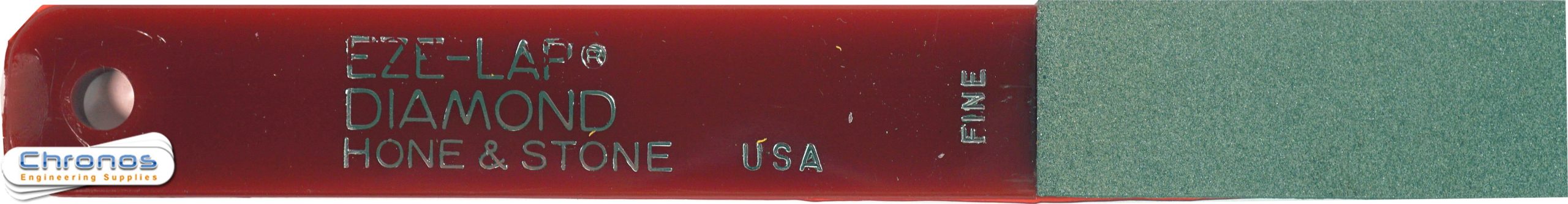

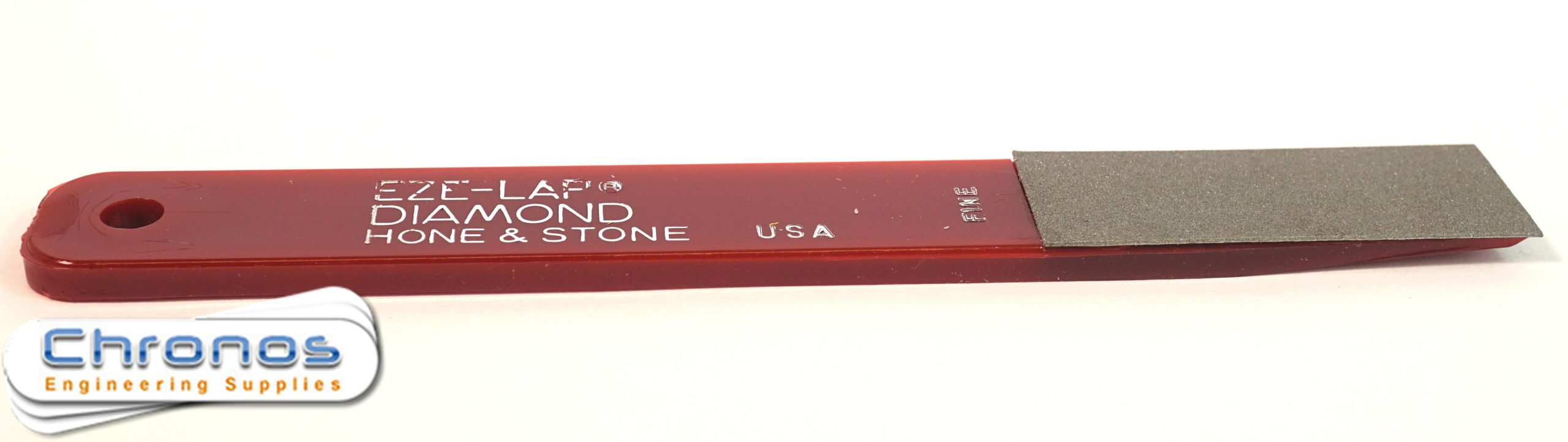

3/4″ x 2″ Diamond Pad on a 6″ x 3/4″ Plastic Handle.

Getting Started

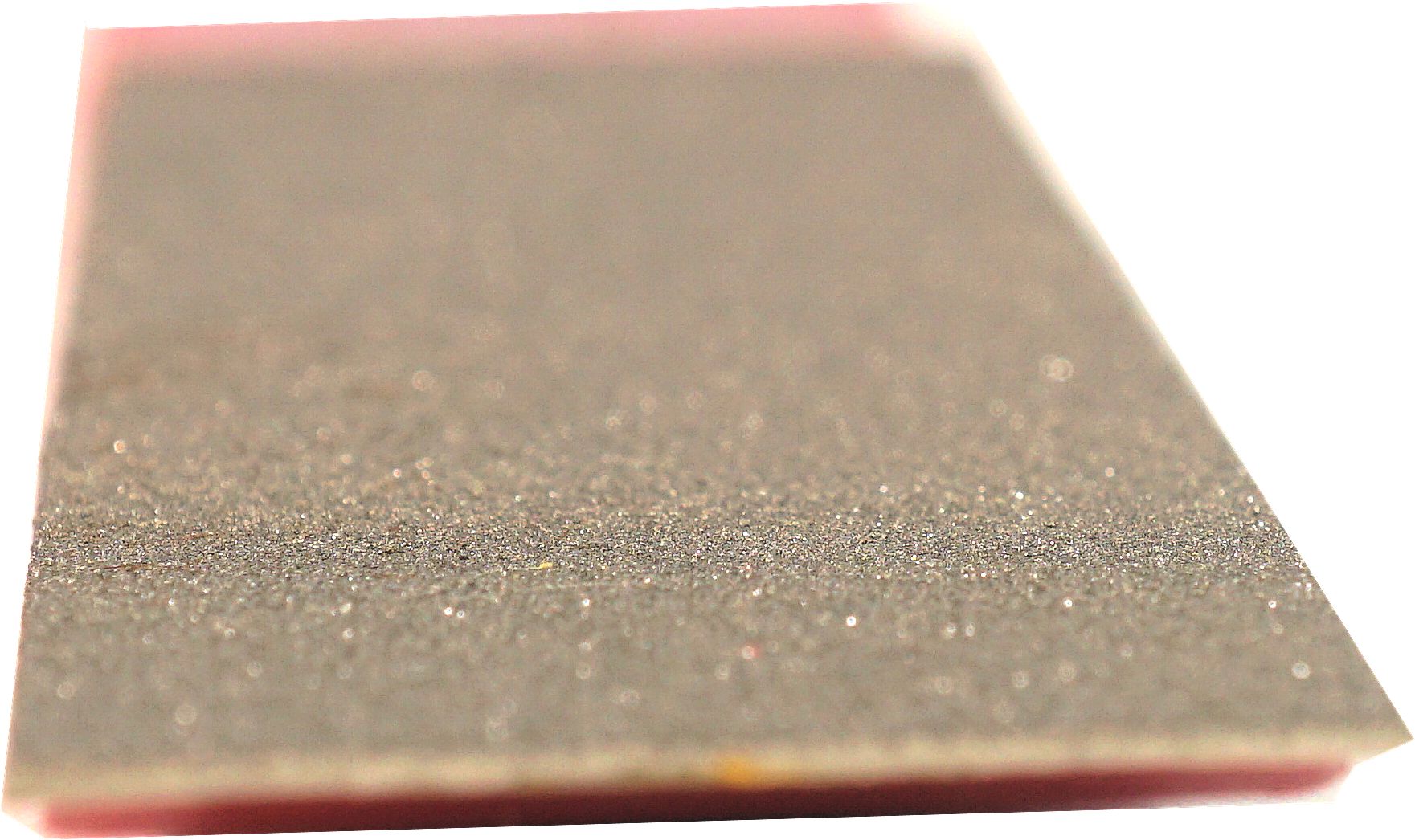

When first using your Eze-lap Sharpener the surface will appear to be quite coarse in texture. This roughness is due to the final manufacturing process and will be removed immediately with heavy filing action

As the diamond wears down more and more diamonds are exposed and the sharpener cuts faster . When more pressure is applied the Eze-Lap will work even faster . Built with our superior materials and technology these sharpeners could last a lifetime !

Directions for use on Knives

Lay blade flat on diamond abrasive surface , elevate blade spine slightly (approx thickness of the blade) , rub in a circular motion periodically alternating sides . Start with a firm pressure to establish edge , once edge is established finish with light pressure .

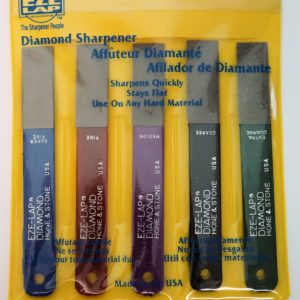

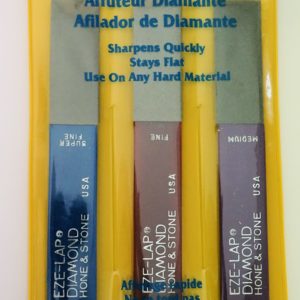

Ideal for accessing hard to reach places these continuous diamond carbide sharpeners are extremely effective on saw blades, tungsten carbide router cutters, kitchen knives and axes. They colour coded handles and have an overall length of 6″, with revealed diamond edge of 2″ by 3/4″.

They feature Eze Lap’s patented diamond bonding process to ensure the flattest, most consistent diamond tool sharpening stone. A special heat treatment process bonds the highest quality industrial grade diamond particles in a stainless alloy. This results in a long lasting hard wearing surface that allows you to sharpen tungsten carbide, high speed steel, stainless steels, ceramic and even specialist tool steels.